Checking Out Innovative Production with In-Mold Decorations

Wiki Article

Mastering In-Mold Decorations: Methods, Trends, and Finest Practices for Ideal Outcomes

In the world of manufacturing, the art of in-mold decors stands as a critical facet of product style and manufacturing. In-Mold Decorations. By diving right into the approaches, trends, and ideal practices that underpin effective in-mold decoration processes, services can unlock a world of possibilities that not just elevate the visual appeal of their products but also streamline production performance and strengthen consumer involvement.Material Selection

Material selection is a vital aspect of understanding in-mold designs, as it directly affects the top quality and longevity of the last item. When choosing products for in-mold decorations, it is crucial to think about variables such as compatibility with the molding procedure, the preferred aesthetic end result, and the environmental problems the product will certainly deal with. Thermoplastic products like polycarbonate, ABDOMINAL, and polypropylene are commonly made use of for in-mold designs as a result of their adaptability and ability to attain elaborate layouts. These materials provide excellent moldability, making it possible for producers to develop complicated shapes and patterns with accuracy.Furthermore, materials with high warmth resistance are preferred for in-mold decors, specifically for items that will be exposed to elevated temperatures during their lifecycle. By very carefully choosing the appropriate product for in-mold decorations, suppliers can enhance the total top quality and toughness of their items, meeting the assumptions of both clients and end-users - In-Mold Decorations.

Style Development

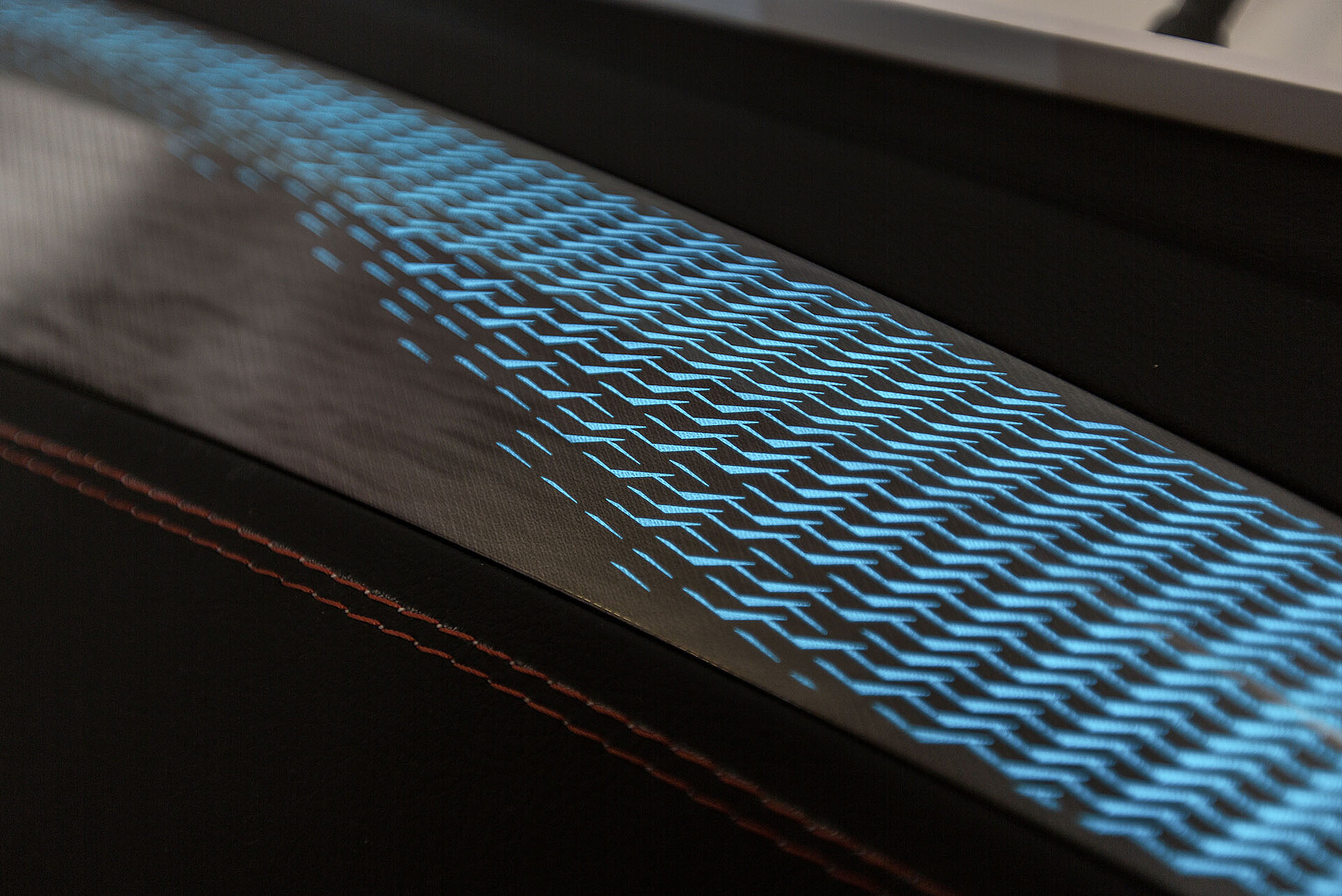

A vital consider advancing the field of in-mold decors is the constant exploration and execution of design technology strategies. Design advancement plays a crucial function in boosting the aesthetic charm, functionality, and overall high quality of products produced using in-mold design processes. By incorporating cutting-edge layout aspects, producers can separate their products in the marketplace, draw in consumers, and remain in advance of competitors.Among the essential aspects of layout advancement in in-mold decorations is the assimilation of complex patterns, textures, and graphics that were formerly testing to accomplish with typical decoration approaches. Advanced innovations such as 3D printing and electronic style tools enable developers to create complex and detailed styles that can be effortlessly moved onto molded components. Additionally, making use of dynamic shades, metal surfaces, and special results like gloss or matte textures can better boost the visual allure of in-mold decorated items.

In addition, design development prolongs beyond aesthetic appeals to encompass functional enhancements such as ergonomic shapes, integrated functions, and customizable elements that accommodate particular customer demands. By accepting design development, makers can open brand-new possibilities for item, customization, and creative thinking distinction in the affordable landscape of in-mold decorations.

Production Efficiency

Effective manufacturing procedures are essential for equating the cutting-edge layouts created in the field of in-mold decorations right into high-grade ended up products that meet market demands and customer assumptions. In the realm of in-mold designs, manufacturing efficiency encompasses numerous crucial elements that add to the total success of the production process. One essential element is the optimization of mold and mildew design and tooling to make certain smooth and exact decor transfer onto the end product. By fine-tuning mold and mildew arrangements and spending in high-grade tooling products, makers can improve efficiency and uniformity in why not try here production.Additionally, applying automation and robotics in the assembly line can considerably improve performance by streamlining repeated jobs and lowering the margin of mistake. Automation not just accelerates the manufacturing process yet likewise enhances accuracy and repeatability, causing an extra uniform and high-grade final result. Furthermore, adopting lean production concepts, such as just-in-time inventory administration and waste reduction methods, can additionally boost manufacturing efficiency by reducing downtime and optimizing resource use. In general, an alternative strategy to production performance is vital in optimizing the possibility of in-mold decoration techniques and achieving optimum cause the competitive market landscape.

Quality Assurance Steps

What are the key approaches for making sure stringent top quality control steps in the world of in-mold decorations? Quality control procedures are paramount in in-mold decoration processes to guarantee the manufacturing of top notch and flawless completed products.Using innovative innovations such as computerized evaluation systems can additionally enhance the quality assurance process by supplying trusted and precise information for analysis. These systems can find imperfections that may be missed by hands-on examinations, therefore improving overall product top quality and uniformity.

Normal training and growth programs for employees associated with the in-mold design procedure can likewise add to preserving premium criteria. By educating team on best techniques, quality assumptions, and the value of focus to detail, companies can foster a society of quality awareness throughout the company.

Customer Charm

To improve the bankability of in-mold decoration products, comprehending and providing to customer preferences play a crucial duty in establishing their allure and success. Customer allure in in-mold decors is affected by different aspects, consisting of style visual appeals, color choices, toughness, and overall functionality. Consumers are progressively seeking personalized and distinct products that mirror their originality and design. Offering modification alternatives such as individualized styles, color variants, and textural aspects can significantly enhance the allure of in-mold design products.

Verdict

In-mold read what he said decors supply a versatile and efficient method to enhance product visual appeals. Mastering in-mold decors calls for an all natural strategy that takes into consideration all elements of the manufacturing procedure to make certain success.In the world of manufacturing, the art of in-mold designs stands as a crucial element of product style and production. Style development plays a critical duty in enhancing the aesthetic charm, functionality, and general high quality of items produced using in-mold design processes.One of the vital elements of layout advancement in in-mold decorations is the assimilation of elaborate patterns, appearances, and graphics that find this were previously testing to achieve with typical design approaches.Effective manufacturing processes are crucial for equating the cutting-edge styles created in the field of in-mold designs right into top notch finished products that fulfill market demands and customer assumptions. Providing modification options such as tailored designs, color variants, and textural elements can dramatically enhance the charm of in-mold design items.

Report this wiki page